DHR/AR Rheometer: Setting Up a Step (Transient) Creep Test

Overview

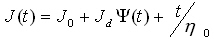

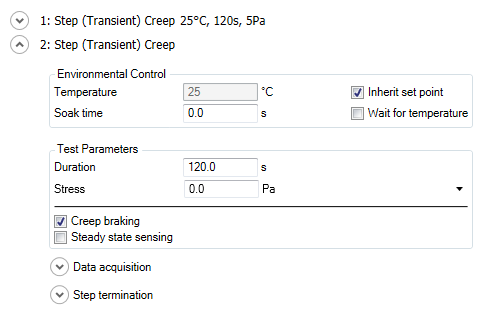

The response of a material to a shear stress step s(t) = so h(t) at time t = 0, is the shear strain g(t). The material function is the compliance J(t):

J(t) can be separated into 3 terms:

with Jo the time independent elastic compliance;Jd the retarded compliance and Y(t) the creep function with Y(0) = 0 and Y(∞)= 1

In a creep test, a step stress function is applied to the material and the deformation is recorded over time. During the creep phase, the strain increases to reach a steady state flow eventually.

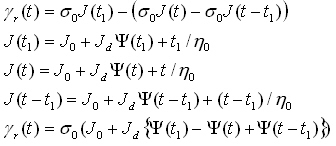

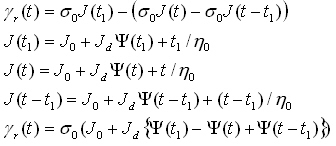

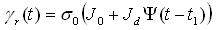

If the stress is removed after a time t =t1 the recoverable deformation (recoil) g r (t) is obtained.

In the Recovery phase, the elastic energy stored in the material, drives the strain back to an equilibrium strain.

Back to top

If steady state flow has been obtained in creep, i.e.,Y(t1) = Y(t)= 1:

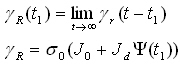

The recovered strain for t→∞ is the total recoverable strain gR (t1) at time t1: If no steady state flow has been obtained during creep (Y(t1)#1), gR reduces for t→∞

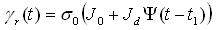

If steady state flow is obtained during creep, gR(t1) reduces for t→∞ to:

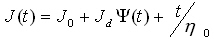

The steady state compliance Je is the sum of Jd and J0 .

Creep recovery experiments are inherent to CMT rheometers and conducted in an open loop control.

For elastic fluids, the deformation will recover and a steady state in the compliance will be reached with time. The total compliance at time t1 can be separated into two parts, a recoverable compliance and a non recoverable compliance. From the recoverable compliance the equilibrium compliance is obtained, however, only when steady state flow was reached during creep. From the non-recoverable compliance, the viscosity can be obtained.

Typically a creep recovery experiment is time-based. Steady state sensing algorithms are available to terminate the creep, as well as the recovery, when equilibrium has been reached.

Back to top

Test Setup

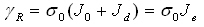

To select a Step (Transient) Creep test, see Using Experimental Procedures for detailed instructions.

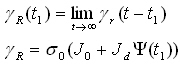

When you perform a Step (Transient) Creep test, the following parameters need to be chosen.

Environmental Control

Select the following environmental control parameters:

- Temperature: Maintains temperature selection throughout the test. Enter the desired test temperature, or select Inherit set point to maintain the previously specified temperature at the start of this step. The temperature range is dependent on the configuration of your instrument and the installed environment control system.

- Soak time: The amount of time to delay data acquisition at the start of the step, typically to allow for temperature equilibration. This time is measured from the start of the step if Wait for temperature is not selected, or from the point at which the measured temperature becomes stabilized at the specified Temperature, if Wait for temperature is selected. Because of the mass of the sample, test fixtures, and environmental control systems a "soak time" (i.e., time to equilibrate at temperature) is recommended, particularly when starting steps at different temperatures. A five-minute soak time is sufficient for most samples in cases where the change in temperature is not too large.

This time is also used at each increment temperature.

- Wait for temperature: Select this option to wait until the measured sample temperature reaches the specified temperature before beginning data acquisition. If you wish to begin data collection without waiting for the sample temperature to reach the specified value, disable this option.

Back to top

Test Parameters

Set up the following test parameters.

- Enter the Duration time of your experiment.

- Choose between Stress or Torque, then enter the desired value. This parameter is defined as the specified step stress to be applied to the sample. This value, along with the sample geometry and dimensions, is used to calculate the peak torque or force to apply to the sample during the measurement. The stress can be selected to simulate real-life end-use conditions, or it can be a value selected to be within the linear viscoelastic range of the sample, and still provide a large enough strain signal to ensure good data.

- Creep braking: Creep braking compensates for the kinetic energy stored in the rotating geometry at the end of the creep step. This kinetic energy is compensated by applying the required reactive torque (opposite sign) for 10 ms to stop the geometry from rotating. This feature prevents the strain from overshooting and guarantees that only the elastic energy stored in the sample is used for the sample recovery in the subsequent creep recovery step where the stress is set to zero.

- NOTE: The Creep braking check box is only present when the stress or torque under Stress Parameters is zero (0.0). If a non-zero value is entered, the Creep braking option is not active.

- Check the Steady state sensing box if you want to place a condition on the number of data points required for calculation of the steady state. Enter the following parameters:

- The % Tolerance default value is five percent of the total number of data points in the test. Change the percentage, if desired.

- Over time period: This is the time period within which the tolerance is verified.

- Consecutive within tolerance: Number of repeated verification steps required before accepting steady state flow.

Data Acquisition

- Save image: Select to store images of the test within the data file for future recall when using the Camera accessory.

- Select the Fast sampling option, or manually set the data sampling conditions.

In the fast sampling mode, data acquisition decreases logarithmically with time.

- If fast sampling is not set, data are acquired linearly.

- Enter the Initial time between samples.

- If Adjust time between points is selected, the linear sampling rate is adjusted (and time between data points is doubled) after a given number of data points.

- Enter the Number of points before time changes.

Back to top

Step Termination

TRIOS software allows you to define conditions in which a step is halted ahead of its normal termination conditions (Limit checking). You can use this to ensure that, for instance, the instrument does not over speed or apply excessive strains.

Rather than running a step for a certain amount of time, you may wish to run it until stable data is obtained. You can set an Equilibrium limit (such as the viscosity value becoming constant when running a single shear with time) that will stop the currently active test.

Back to top